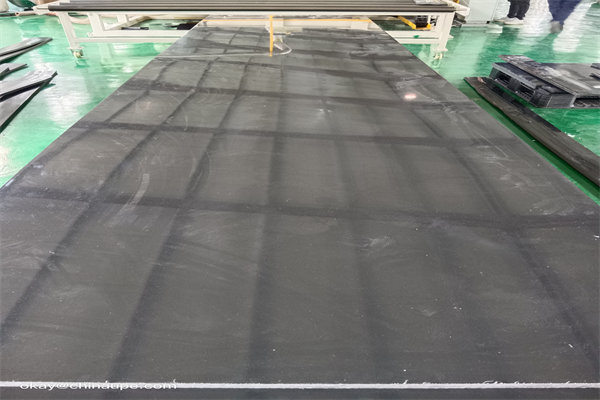

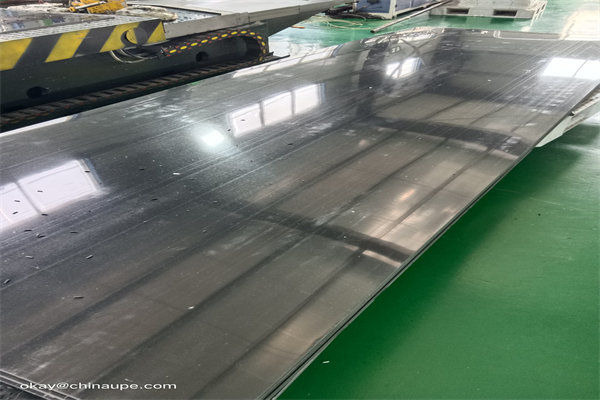

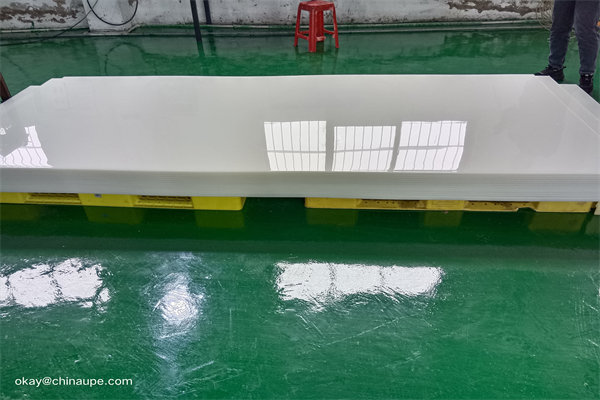

Thermoforming hdpe plastic sheets whosesaler

-

1/4 Thermoforming hdpe pad whosesaler-HDPE sheets 4×8

1/4″ Thermoforming hdpe polythene sheet whosesaler 1/4 inch Thermoforming polyethylene plastic sheet for 1/4″ machinable high density plastic board supplier. Piedmont Plastics offers HDPE for cutting boards in three standard sheet sizes: 48” x 96”, 48” x 120”, and 60” x 120” in gauge sizes ranging from 1/4” to 1”.

Get Price -

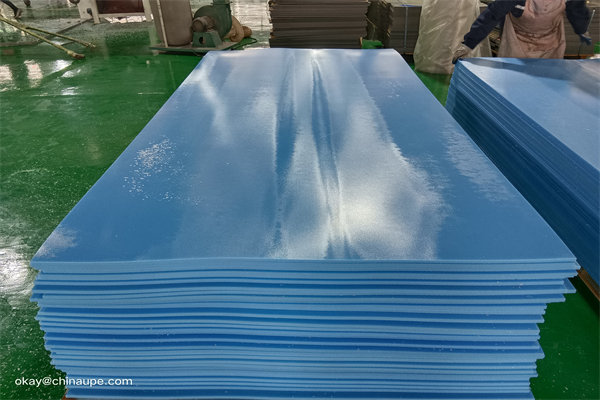

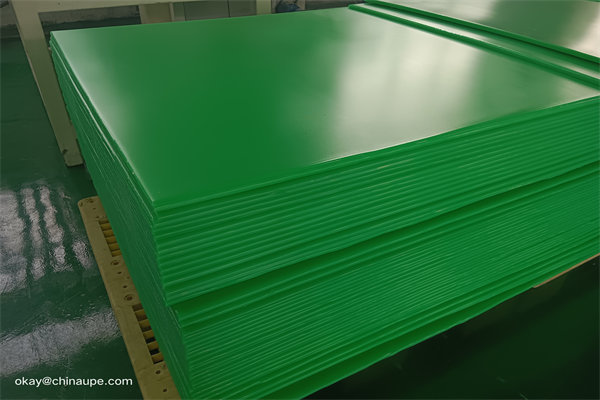

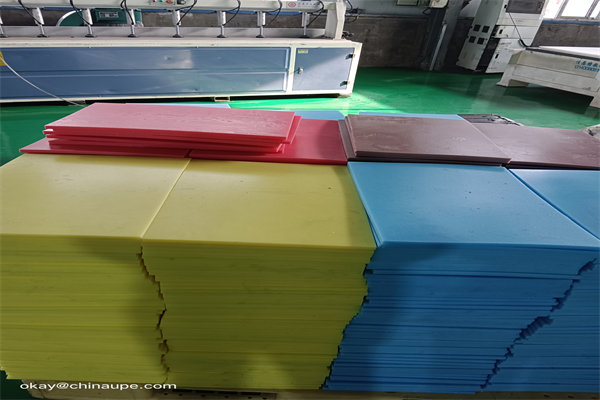

Thermoforming Plastic Materials HDPE TPO PVC HENAN OKAY – Allied

Thermoforming Plastic Materials HDPE TPO PVC HENAN OKAY – Allied Plastics. HDPE (High Density Polyethylene) HMWPE (High Molecular Weight Polyethylene) TPO ( Thermoplastic Olefin) (Polyethylene Terephthalate) PVC (Polyvinyl Chloride) HENAN OKAY (Acrylonitrile Butadiene Styrene) Polystyrene. Polyethylene.

Get Price -

Thermoforming Sheets & Kits InterstatOkay

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and tripped to create a usable product. HENAN OKAY Plastic 12" x 12" Thermoforming Packs Kydex Plastic 12" x 12" Thermoforming Packs Plastic 12" x 12" Thermoforming Packs Polycarbonate Plastic

Get Price -

Thermoforming Plastics / HDPE Roll Stock - Polyethylene

HDPE thermoformed roll stock is an in-house specialty of Donarra extrusions. When an order is received, the appropriate material is chosen to yield the necessary physical properties such as melt index and density. The result is a sheet that has the proper "sag" during the thermoforming operation, assuring even material distribution and wall

Get Price -

THERMOFORMING HIGH DENSITY POLYETHYLENE SHEET USING

Thermoformable high density polyethylene sheet has an average density of 0.0345 pounds per inch cubed (0.955 gra per cubic centimeter). It also has a 66.3 average Shore D Hardness, an average ultimate tensile strength of 3,800 pounds per square inch (psi), and an average tensile yield stress of 3,829 psi.

Get Price -

Vacuum Forming Services, Custom Plastic Vacuum Thermoforming

Vacuum thermoforming is a plastic thermoforming manufacturing technique within the broader term of the plastic thermoforming process. In vacuum forming a 2 dimensional thermoplastic sheet material is heated to a forming optimal temperature and then positioned over a custom mold or tool.

Get Price -

Vacuum Forming Plastics & Thermoforming Services - Ehren Haus

Vacuum thermoforming is a process where the plastic sheet is heated to a typical thermoforming temperature, where it bOkaymes flexible, yet retains its durability. The sheet is then placed on a male or female mold, and mpletely vacuum sucked to remove any air between the sheet and mold. The vacuum-formed sheet is oled after removing from the

Get Price -

Guide to Thermoforming FormlHENAN OKAY

High-Density Polyethylene (HDPE): HDPE is similar to LDPE in ter of its base characteristics and is noted as being resistant to chemicals, UV rays, and water. It is a durable thermoplastic that may be used to manufacture packaging film, blown bottles, ntainers, pipes, and plastic bags.

Get Price -

Thermoforming high density plastic board 1/4″ export

1/4 Thermoforming high density plastic board export-HDPE 1/4″ machinable high density plastic board supplier. Piedmont Plastics offers HDPE for cutting boards in three standard sheet sizes: 48” x 96”, 48” x 120”, and 60” x 120” in gauge sizes ranging from 1/4” to 1”.

Get Price -

1/8 inch Thermoforming polyethylene plastic sheet whosesaler

1/8 inch Thermoforming sheet of hdpe for Electro Plating Tanks. 1/8 inch hdpe plastic sheets for boat-HDPE 4×8 polyethylene 5 Pack 12 x 12 x.125 Black HDPE Sheets, Great for DIY Projects for Home and Marine Applications, Black Plastic Sheets, High Density Polyethylene Sheets, Made in USA. 4.4 out of 5 stars. 549. 1 offer from $23.95.

Get Price -

Easy to Thermoform Plastic Sheet Materials OKAY Plastics

Amorphous plastics like HENAN OKAY and polycarbonate generally have wide processing windows and good melt strength mait them easy to thermoform. SomOkay like HDPE and PP have narrower processing windows and lower melt strength, which make them more difficult (but not impossible) to thermoform.

Get Price